Most People don’t realize how many types of patches there are.

We can create patches in many ways, including: fully embroidered, embroidered with material background, photo emblem, photo combo, photo over embroidery, or woven.

We offer a standard twill background, or you can choose a specialty fabric. You can choose the type of border and backing you want for your patches also.

To help you we have compiled a list of all your options with descriptions of each so you can decide which is best for you. Click the arrows to expand the description.

Patch Products

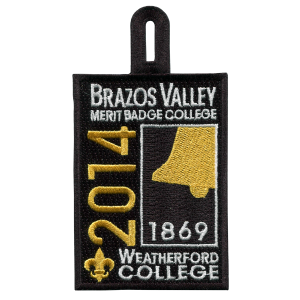

- Embroidery-On-Twill

This is a Standard Embroidered Patch. The main part of the design is embroidered with the base material showing in the background. This type of patch is one of the most cost efficient.

Materials to Choose From – Standard Twill:

- Embroidery-On-Twill

Felt:

- Embroidery-On-Felt

or Suede:

- Photo-Combo

A Photo Print patch is where we take an image or art and dye sublimate it onto a base material (twill or satin only). This allows for extra small or highly detailed images that will not translate well to embroidery. This is also a very cost efficient patch.

- Photo-Over

This is a very popular way to use Photo’s with embroidery. We fully embroider the patch design with white thread only and then dye the image onto the thread. This gives us the versatility of a photo with the look and feel of a fully embroidered patch.

A woven patch uses thread to weave your design (think clothing tags). This type of emblem allows for greater detail than regular embroidery.

- woven patch

- Chenille

Chenille patches use a type of loop embroidery. Most people associate this with Varsity Letters, but it is a great option to add both height and feel to your design.

- Merrow-Border

Also known as an over-lock border, this border wraps from the front of the emblem to the back.Hot Needle Cut:

- Hot-Needle

Or cut edge patch, allows for more intricate shapes and is less bulky.

Button Loops:

- Button-Loop

3D Foam:

Glow in the Dark Thread:

- Glow-In-The-Dark-Patch

- Glow-In-The-Dark-Night

Grommets:

- Col-Grommet

Ghosted:

- Ghosted Patch

Key Ring:

- Key-Ring

Metal Products:

How are they made?

– Photo / Silkscreen pins are first die cut in your design shape from a metal sheet and polished smooth. Then a base color is applied to which your design will be printed either using a laser printer for Photo or a Silkscreen process. Finally a layer of clear epoxy coating is applied to protect your design.

- Lapel-Pin-Web

How are they made?

– Die Struck Pins begin with a base metal (in the plating of your choice). A die is created for your individual design and then stamped onto the metal. Then the recessed areas are sandblasted to enhance detail. If you choose color enamel in your design, the enamel is then placed in the recessed areas of the pin. Finally the pins are polished and are given an epoxy coating if desired.

How are they made?

– Cloisonne pins start the same way as Die Struck pins. A die is made of your design and stamped into the base medal to create a raised image. Then the recessed areas are filled with glass like colored resins. The pin is then fired in ovens at 1700 degrees.

1. Brass with Gold or Nickel Plating (Cloisonne or Die Struck)

2. Iron with Gold or Nickel Plating (Die Struck)

3. Stainless Steel (Photo)

4. Aluminum (Photo)

Patch Design Resources

Contrast is Always Better

Minimum size lettering is 1/8″

Click to Open or Download Krelman Thread Color PDF2

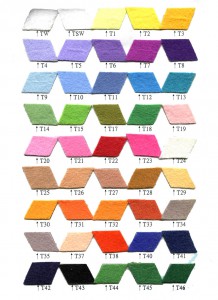

Below are the available felt colors we offer. To designate a felt-type in your order please list the reference number listed under the felt samples. (Click Images To Enlarge)

Please note that colors viewed on a computer monitor may vary slightly from computer to computer.